Selecting the appropriate equipment for your metal production job is essential to producing the necessary results quickly and precisely. Metal folders and handbrakes are among the many instruments that are crucial for bending metal sheets. Despite having the same primary function, these instruments may be used for various tasks and have varying degrees of precision and project size. This post delves further into the differences between metal folders and handbrakes, helping amateurs and fabricators choose the best option for their metalworking requirements.

Comparing Handbrakes and Metal Folders for Metal Bending

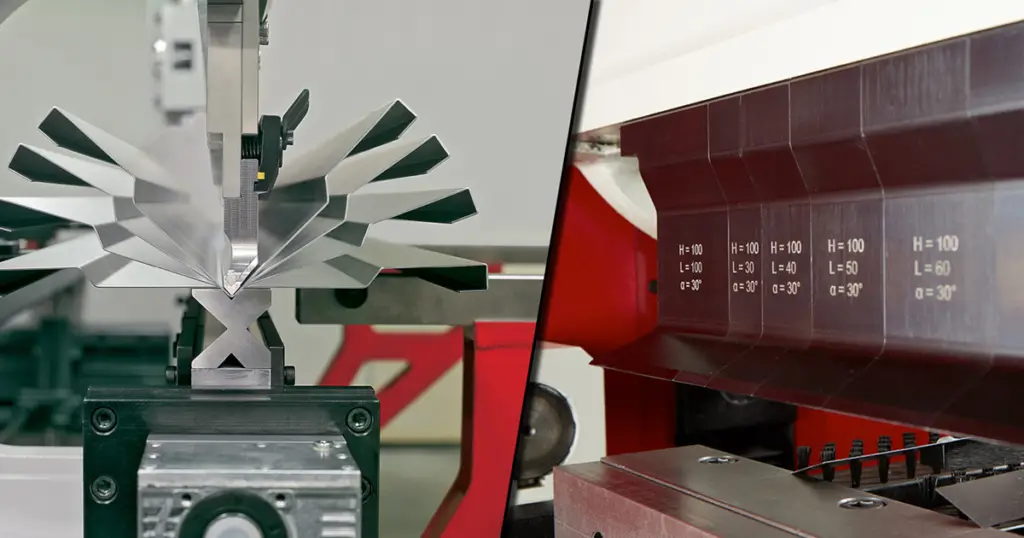

Metal Folders: The Accurate Suppliers

Metal folders provide unmatched precision in metal bending operations due to their superior design and performance. The method they use is to clamp the metal sheet between a clamping bar and a fixed bed, then bend it over a folding beam. This mechanism is beneficial for bespoke metal projects and high-volume manufacturing where consistency is crucial since it enables exact bends, little setup time, and repeatability. Metal folders are helpful in production because they can handle various materials and thicknesses.

Metal folder automation reduces human labor and error-proneness while increasing metal manufacturing efficiency. Operators may create intricate bending sequences by using sophisticated control systems in conjunction with automation, further boosting productivity.

Handbrakes: The Adaptable Icons

Handbrakes, sometimes called manual press brakes, are classic metalworking instruments valued for their adaptability and ease of use. Because the metal sheet must be manually bent over a die, they are appropriate for low-volume applications or settings where accuracy is less critical. Handbrakes perform well in workshops where versatility and adaptation are essential since they don’t require much setup time and can be readily adjusted to various metal kinds and thicknesses.

Handbrakes provide the benefit of tactile feedback throughout the bending process, which some operators prefer for particular artistic or specialized work, even though they require more labor than metal folders. They are also more affordable to start and maintain, making them a good option for small workshops or budget-conscious hobbyists.

Selecting the Best Option for Your Metalworking Requirements

Project Details and Volume

The project’s size, intricacy, and volume should all be considered when choosing between metal folders and handbrakes. Metal folders are preferred for large-scale jobs needing great precision and repeatability. They’re perfect for productive manufacturing lines since they can manage intricate bending sequences with little human assistance. However, handbrakes are better suited for smaller, customized applications where manual control and flexibility might be helpful.

Accuracy and Command

For many industrial operations, precision metal folding is essential. Metal folders provide enhanced control and precision for projects requiring precise angles and reliable results. In projects where minor deviations are allowed or where the human element adds value, handbrakes provide competent operators plenty of control.

Expense Factors

When choosing tools for fabrication, cost evaluation is crucial. Metal folders are expensive, but their great productivity and efficiency make them worth it. They are economical for businesses where their sophisticated features and automation can be fully used. On the other hand, handbrakes are more affordable and require less maintenance, which makes them available to amateurs, small enterprises, and startups.

Upkeep and Extended Life

Any piece of equipment used in metalworking has to be maintained. Maintenance for metal folders and handbrakes differs; for best results, folders must have their hydraulic systems serviced and software updated regularly, while simpler handbrakes usually need essential maintenance and sporadic adjustments. Planning for operational downtime and long-term equipment expenditures can be aided by thoroughly understanding the maintenance requirements.

Workshop Area and Operator Expertise

Practical factors include operator skill levels and space limitations. More floor area and skilled operators who are acquainted with their complex controls are frequently required for metal folders. Handbrakes are more user-friendly for a wider variety of users since they are more straightforward, fit better in tight areas, and need less specialist expertise.

Flexibility and Future Requirements

It’s important to consider future projects and changing fabrication demands when deciding between metal folders and handbrakes. Metal folders provide scalability for companies expecting to develop or diversify into new sectors demanding delicate metalworking processes because of their programmable features and ability to accomplish complex bends. They are, therefore, a long-term investment for businesses wishing to increase their capacity without buying new equipment. Although handbrakes are less adaptable for intricate operations, they are simple and easy to modify for various materials and simple projects, so they may still be a valuable addition to more sophisticated gear or companies that specialize in small-scale, custom, or artisanal manufacturing.

Environmental Aspects to Take into Account

The influence of metalworking equipment on the environment is crucial in decision-making. Metal folders can lower electricity usage and the carbon impact of activities, especially those with contemporary, energy-efficient designs. Their accuracy and effectiveness also reduce waste by minimizing the amount of scrap metal produced when bends go wrong. However, because handbrakes must be operated manually and consume almost no electricity directly, they are a more ecologically responsible choice for enterprises that want to use as little energy as possible. By considering the environmental effects of your machinery, you can match your metalworking procedures with sustainability objectives and legal regulations, which may result in financial savings and environmental advantages.

In summary

When deciding between handbrakes and metal folders, there are several things to consider, such as the operator’s skill level, availability of space, budgetary limits, maintenance capabilities, and project requirements.

Knowing the advantages and disadvantages of each tool is crucial, regardless of whether you’re comparing metal folders vs. handbrakes for sheet metal bending tools or comparing metalworking equipment for more general requirements. You can choose the best tool to match your metalworking project planning and create fantastic custom metal projects by carefully planning your project, considering efficiency when fabricating metal, and assessing the maintenance requirements for metal folders and handbrakes.